Up until ten years ago plumbers were contracting in high flow, low pressure water jet trucks to clear blocked drains that their eel could not penetrate as the only option to the shovel.

These trucks are large and powerful and very successful when used correctly for cleaning commercial and some residential drainage lines. They work on high volume as opposed to high pressure. The down side to this method of drain cleaning is the size of the vehicle, their inability to quickly refill their on board water tanks for water supply and their jet hose diameter making most residential drain cleaning difficult.

Plumbers were looking for another option that was cost effective and user friendly. An engineer named Noral Hill from the Central Coast designed such a machine that has been modified by plumbers all over Australia to suit their own requirements.

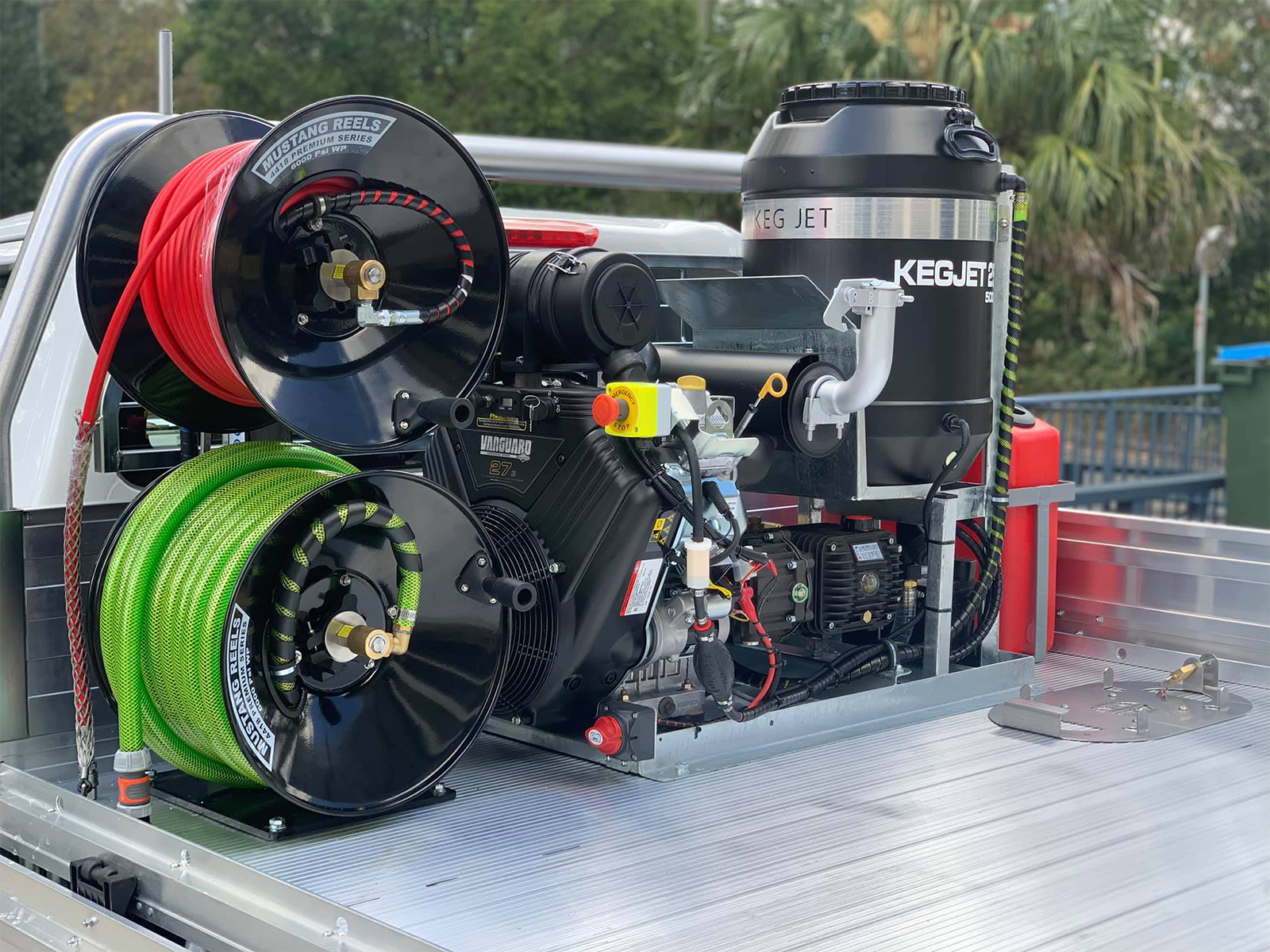

Today these machines take the form of custom built truck mounted units fixed permanently to the plumbers vehicle with remote reels, through to a small water jetter in a frame on wheels with built in water and fuel tanks and a hose reel running over 100m of flexible hose weighing around 100kgs.

These small high pressure water jetters can be wheeled straight to the job and start work quickly once connected to a normal garden tap. A base machine runs 110m of hose with a smooth outer surface reducing friction inside the pipes. They come with a variety of nozzles for use in 20mm to 225mm pipes with the ability to pull through toilet pans and tight pvc gully traps.

The only competition to the water jetter in its class is the eel. An eel gets its working energy from back at the machine, the water jet energy starts at the source of the backpressure which is the nozzle at the end of the hose where the power is most needed.

With the use of root cutting turbines, a drain cleaned by a high pressure water jetter is left 30% cleaner than using an eel. There are many places an eel cannot go where a jetter hose travels with ease. The average hoses used by plumbers today are 1/4", 3/16" and 1/8". Combine the jetter with a boiler and these machines are unstoppable in old grease filled commercial drains.

Their key advantages are their fast setup requiring no external 240v power supply, single operator operation, key ignition, time saving on each job, flexible drain cleaning and thorough root removal ability.

Don't get me wrong, there is always a place for the old eel, but with all these advantages, why would you buy anything else? You won't get much change from 10 big ones when you start looking around for a decent unit but when the job profits start rolling in you'll wonder why you never cottoned onto the idea years ago.