Mustang Nozzles

Mustang Nozzles supports the plumbing industry today by designing and producing high-performance drain cleaning equipment under the banner 'Mustang Nozzles' ™ and 'The Jetters Edge' ™. The operators (drain technicians) who use our equipment demand high-quality products at the right price and that's what we give them. We specialise in High-Pressure Water Jetting Equipment and manufacture a wide variety of parts to suit most water jetting machines on the market today. We back up our products with a lifetime 'manufacturing defects' warranty and offer professional drain cleaning advice from experienced operators along with in-house or on-site training.

Most of our profits go back into research and design so that we can move forward with technology and charity work. Some of our older designs include a set of colour CCTV glasses worn by the operator attached to a mini CCTV camera on the end of the 'Root Ranger' ™ root cutting turbine, (it's a bit like virtual drain cleaning), a stainless steel 'Mustang Pump' ™ venturi with hoses and hose carrier that connects to the water jet to pump large volumes of water at over 6m head, a tip cleaner in a capsule for nozzle cleaning that actually works, a set of 5 coloured dye tablets in a cylinder so several drains can be tested at once - unlike normal powder dye that can cause a real mess!

A common problem operators had, who used quick release couplers in silted up drains, was the removal of the nozzle from the end of the hose when a nozzle change was required. The silt would get in behind the sheath on the quick release coupler making it nearly impossible to remove. We designed and patented a 'Silt Proof Quick Release Coupling' made from brass or stainless steel preventing the coupler from ever jamming again. Although this cost thousands of dollars, 43 revised drawings and many months to build, it only added a few dollars to the end product saving the operator time and money.

Keeping in mind the use of our precious water supply, we now make all our nozzles using our new 'Water Smart' technology. They use less water but have the same result. They are also made of a unique stainless steel material we have cast and drawn. After the drilling process, we heat treat the stainless to make them last a lifetime. We could build them cheaper but we have found operators today are quality-focused, not price-focused.

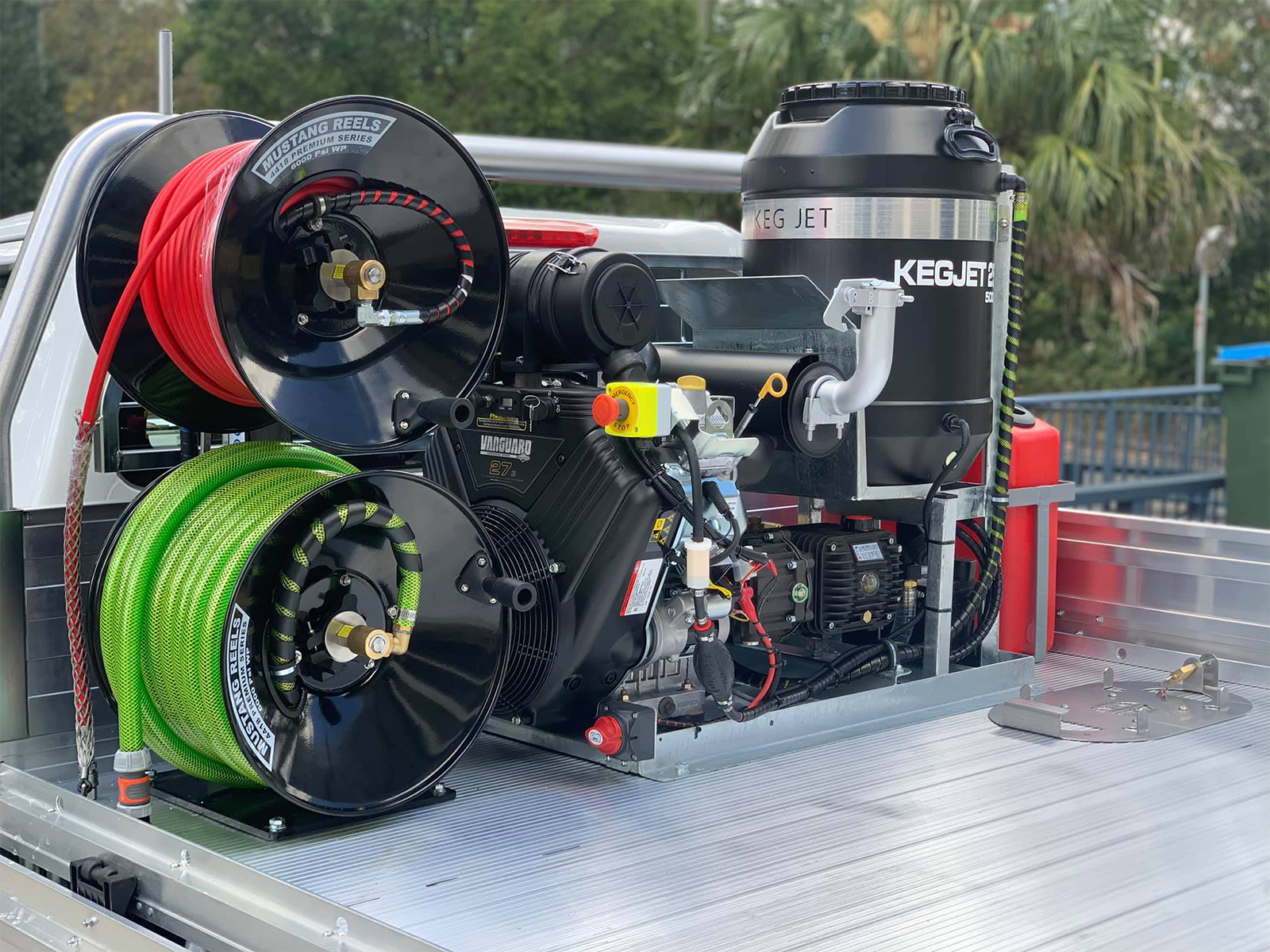

The most popular products we sell today are the 'Root Rat' ™ nozzle, the 'Root Ranger' ™ nozzle, and the Remote Mini Reel. The 'Root Rat' nozzle is used to penetrate a blocked drain and was designed after many tests were carried out to see how the nozzles actually work using specially modified CCTV equipment inside blocked drains. We found that the head of the nozzle was where most of the work was done so that is where we put the main penetrating jets.

The 'Root Ranger' ™ nozzle is used after a hole has been penetrated through the blockage. It is the only nozzle in the world that will completely remove grease, roots and debris thoroughly away from the pipe walls and inspection caps without damaging the pipes. We export over 2000 'Root Ranger'™ nozzles annually. We have now fitted a forward-firing removable jet to the nose cone of this nozzle facilitating both penetration and root cutting without the need to change the head. This nozzle now has an International Patent.

The Remote Mini Reel allows the operator to work away from the pump in safety. If the hose exits the drain unexpectedly, the operator can shut down the water supply before a serious injury occurs without having to run back to the pump. The 60m of 3/16" thermoplastic hose on the stainless steel remote reel allows access around toilet bowls and tight traps. A 20m 1/8" whip hose is also available for smaller traps and bends.

The market for drain cleaning today is bigger than ever with many plumbers starting up specialised drain cleaning companies alongside their own plumbing company. After a plumber purchases a water jet and a diagnostic drain camera they can not only promise their customer a cleaner drain but they can also offer a full inspection of their drains so problem areas can be located for future repair or preventative maintenance. We help set up plumbers with our equipment every day. Those who purchase the complete jet and camera package outlay over $20k but generally come back to buy another water jet within 6 months because the profits made from owning the equipment pay for themselves over the 6 month period. Several operators sub-contract their services to other plumbing companies who don't want to buy the equipment, this alone is a lucrative business.

Some plumbers buy a diagnostic drain camera first using it alongside their eel. This is a cheaper way to set yourself up in the drain diagnostic market. The camera quickly determines the fault in the drain after it has been cleared. A diagnostic drain camera can cost as little as $5k and make you four times that amount in a year. For $12k you can buy a camera with a built-in sonde so you can locate what you find. We have just finished designing a water jet nozzle that screws on the back of the new Ridgid Sonde. This means you can clean a blockage with the water jet, snap on the sonde, jet it back down the drain and locate the area of the blockage without the use of a camera or push rods!

A new sideline to drain cleaning taking off in Australia, but widely used in the US, is the effective long term preventative maintenance of drainage using Root Foam Chemical treatments. A licensed root foam applicator can treat up to 10 properties a day. The advantage of root foaming is that it inhibits the tree root regrowth using EPA approved herbicides. A tree root in a drain cut using an eel or water jet will grow back stronger causing structural damage to the pipes eventuating in a collapsed pipe. A tree root that is chemically treated will grow back weaker as its stem cells are damaged causing retarded growth without killing the tree and if treated properly will only need application every 2 years after the initial 12-month applications.

We have secure patents and registered designs on our products to protect cheap dangerous products from entering the market. It is surprising that after all the time and effort we put into building safe reliable products for the industry, plumbers and water jet operators will take our products and attempt to have them reverse engineered. If they only knew the expense of pressure testing each part to a standard way above Australian Standards, putting patents and registered designs in place, the cost of carrying public indemnity and liability insurance, and the hours spent on R&D then they may understand. We get to hear about everyone who attempts this as the engineering industry has an effective information network across Australia. You would be surprised to know the reputable firms who are trying this on just to save a few dollars and put themselves and their staff at risk.

Ask for a Mustang when you order your next nozzle, you will be supporting Australia and your industry.

See our Product section for a complete range of high-pressure drain cleaning equipment.